Hot-Dipped Galvanized Steel Strips – High Strength and Rust Resistance

Hot-Dipped galvanized steel strips greatly resist corrosion and rust, combine utility and beauty. The zinc coating is firmly bonded to the base metal, and the coating of hot dipped galvanized steel strips are often thicker than electro galvanized steel. They are more suitable for heavy duty applications and outdoor exposure.

HDGSS-01: Three coils of hot dipped galvanized steel strip.

HDGSS-02: Detail structure of hot-dipped galvanized steel strip.

Specifications of hot-dipped galvanized steel strips

- Material: carbon steel wire.

- Surface treatment: hot dipped galvanized.

- Minimum zinc coated: 140 g/m2.

| Item | Thickness (mm) | Width (mm) | Tolerance (mm) |

|---|---|---|---|

| HDGSS01 | 0.7 | 189 | +0, -0.2 |

| HDGSS02 | 1.5 | 86 | +0, -0.2 |

| HDGSS03 | 1.5 | 124 | +0, -0.2 |

| HDGSS04 | 2.5 | 50 | +0, -0.2 |

| HDGSS05 | 2.5 | 65 | +0, -0.2 |

| HDGSS06 | 2.5 | 73 | +0, -0.2 |

| HDGSS07 | 2.5 | 81 | +0, -0.2 |

| HDGSS08 | 2 | 85 | +0, -0.2 |

| HDGSS09 | 3 | 197 | +0, -0.2 |

Features of hot-dipped galvanized steel strips

- High strength.

- Good formability without deformation.

- Anti-high temperature.

- Corrosion and rust resistance.

- Enhanced resistance to staining.

- Easy to transport.

- Durable and long service life.

Applications of hot-dipped galvanized steel strips

- Oil or gas industry.

- Construction.

- Automobile industry.

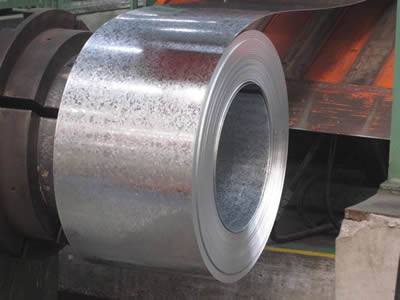

HDGSS-03: Hot dipped galvanized steel strip in workshop.

HDGSS-04: Hot dipped galvanized steel strip package.

Inquiry for Our Product